Sodium Chlorite

Sodium chlorite is a crystalline white powder and has a formula of NaClO 2 . It is stable, commercially available and serves as a strong oxidant. However, it can be lethal if consumed even of minute amount. In addition, it is difficult to burn but it accelerates the burning of organic substances and forms explosive mixtures with certain combustible materials. Sodium chlorite may explode under prolonged exposure to heat or fire.

- Overview

- Application

- Spesification

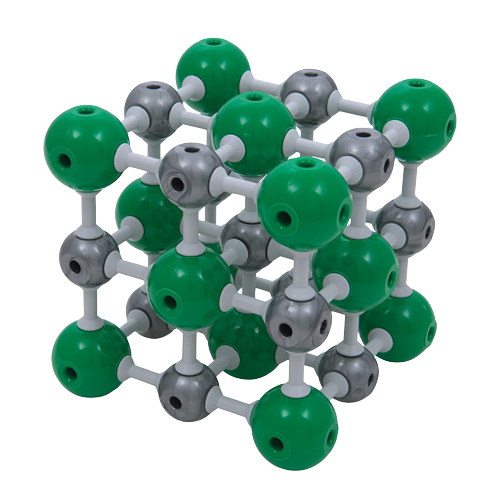

Sodium chlorite is a crystalline white powder and has a formula of NaClO 2 . It is stable, commercially available and serves as a strong oxidant. However, it can be lethal if consumed even of minute amount. In addition, it is difficult to burn but it accelerates the burning of organic substances and forms explosive mixtures with certain combustible materials. Sodium chlorite may explode under prolonged exposure to heat or fire.

Sodium Chlorite

History

The development of sodium chlorite as an industrial chemical began in 1921 when E. Schmidt found that cellulosic fibers could be purified with chlorine dioxide without being appreciably damaged. Unfortunately, chlorine dioxide gas is extremely explosive at high concentrations. These discoveries prompted researchers to look for safe and economical ways to deliver chlorine dioxide for bleaching purposes. The first company to introduce sodium chlorite for this purpose was the Mathieson Chemical Corporation. In 1960, sodium chlorite became the standard material for continuous bleaching operations in the United States, replacing hydrogen. In subsequent years, other uses for sodium chlorite were discovered.

Background

Sodium chlorite is a chemical formula used for water treatment as disinfection and purification. It is produced in massive quantities as flakes or a liquid from chlorine dioxide and sodium hydroxide. In 1920s, scientist discovered sodium cholide formula for textile belaching. Today, sodium chlorite is an important ingredient chemical with gross sales over $18 million annually. Sodium chlorite (NaClO2) is a white or light yellow-green solid as a dried state. The greenish tint comes from trace amounts of CdO2 or iron, which are production residuals. Sodium chlorite has a molecular mass of 90.44 and decomposes at around 392oF (200oC). It is generally soluble in water, but its solubility increases as high as water temprature. Sodium chlorite is a powerful oxidizer that will not combusse on percussion. The anhydrous salt does not absorb water and is stable enough for up to 10 years. Sodium chlorite is used for varies degree of applications. It is used as a disinfectant and purification chemical for water treatment. It is also used as a textile-bleaching and water anti-fouling agent. Additionally, it is used in the pulp paper and electronics manufacturing industries as a bleaching media.

Raw Materials

The primary raw materials used in the production of sodium chlorite are chlorine dioxide, sodium hydroxide, and hydrogen peroxide. Chlorine dioxide is a gas at room temperature. Its color is intensely greenish-yellow. Chlorine dioxide provides the source of chlorine that is converted to sodium chlorite. In production, it is stored as a liquid solution in glass-lined steel containers. Other materials are typically added to sodium chlorite powders or solutions before they are sold. Commercial sodium chlorite bleaching solutions contain special ingredients including anticorrosive agents, buffering agents, chlorine dioxide fume controllers, and surfactants. Anticorrosive agents are used to prevent the corrosion of stainless steel bleaching equipment.

Manufacturing Process

Sodium chlorite is manufactured using sodium chlorate. Using equal amounts of sodium chlorate and sodium chloride, concentrated sulfuric acid is added to yield chlorine dioxide. The chlorine dioxide is then passed through an alkaline solution, sodium hydroxide, and reduced by hydrogen peroxide. This yields sodium chlorite and sodium chlorate and to minimize sodium chlorate production, more hydrogen peroxide is used. With hydrogen peroxide present, it reduces the small amount of sodium chlorate present and allows extraction of sodium chlorite more efficiently.

Sodium chlorite is used to generate chlorine dioxide, which is used for bleaching of textiles, pulp and paper. When sodium chlorite is acidified, it yields chlorous acid and chlorite anion. Chlorous acid will then hydrolyze chlorine dioxide, which in turn breaks down chlorite anion to chloride anion. Chloride anion produced serves as the bleaching agent.

Sodium chlorite, together with zinc chloride, is used to manufacture series of mouthwashes, rinses, toothpaste and gels. They are also used in eye drops and contact lens saline solution. When sodium chlorite is converted to chlorine dioxide, it can be used as disinfectant in hospitals and water treatment

| PRODUCT IDENTIFICATION | |

|---|---|

| CAS NO. | 7758-19-2 |

| EINECS NO. | 231-836-6 |

| FORMULA | NaClO2 |

| MOL WT. | 90.44 |

| H.S. CODE | 2828.90 |

| TOXICITY | Oral rat LD50: 165 mg/kg |

| SYNONYMS | Chlorous Acid, Sodium Salt; Chlorite (sodium salt); |

| PHYSICAL AND CHEMICAL PROPERTIES | |

|---|---|

| PHYSICAL STATE | white crystalline powder |

| MELTING POINT | 175 C (Decomposes) |

| SOLUBILITY IN WATER | Soluble |

| NFPA RATINGS | Health: 1 Flammability: 0 Reactivity: 1 |

| FLASH POINT | Not considered to be a fire hazard |

| STABILITY | Stable under ordinary conditions. Mildy hygroscopic. |

| SALES SPECIFICATION | |

|---|---|

| 80% (SOLID) | |

| APPEARANCE | white crystalline powder |

| NaClO2 | 80.0% min |

| NaClO3 | 5.0% max |

| NaCl | 15.0% max |

| WATER | 1.0% max |

| 25% (SOLUTION) | |

| APPEARANCE | clear to pale yellow solution |

| NaClO2 | 25.0 ± 0.5% |

| NaClO3 | 1.5% max |

| NaCl | 5.0% max |

| SPECIFIC GRAVITY | 1.208 ± 0.02 (at 20C) |

| TRANSPORTATION | |

|---|---|

| PACKING | 50kgs in drum , 200kgs in drum |

| HAZARD CLASS | 5.1 (Packing group: II) |

| UN NO. | 1496 |